Home > Blog > Sharing solutions for common issues encountered in the pilot production line for juice and dairy pro

-

wangfei

Hi there! Welcome to my shop. Let me know if you have any questions.

wangfei

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Sharing solutions for common issues encountered in the pilot production line for juice and dairy pro

2025-10-09 13:29:54

As a "bridge system" between research and development and mass production, the juice and dairy product pilot production line is prone to various issues arising from material properties, parameter mismatches, or equipment conditions during the pilot production phase. Timely diagnosis and precise resolution are crucial for ensuring the efficient operation and reliable data of the juice and dairy product pilot production lines.

Product stratification or precipitation of products

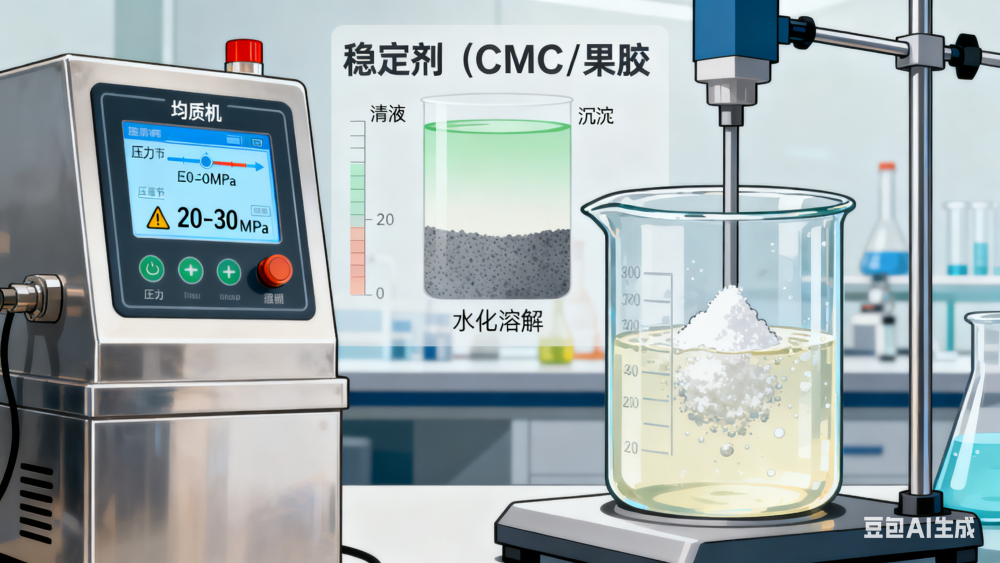

It is more common in fruit juice drinks or dairy beverages. The main reason is insufficient homogenization pressure or improper selection of stabilizers. Check the first and second stage pressure settings of the homogenizer (fruit juice recommended 20-30 MPa, dairy 15-25 MPa + 5-10 MPa), confirm that the pressure gauge is normal. Check whether the stabilizer (such as CMC, pectin, microcrystalline cellulose) is sufficiently hydrated and extend the shear time if necessary. Optimize the ratio of emulsifier and thickener in the formula.

After sterilization, microorganisms exceed standards.

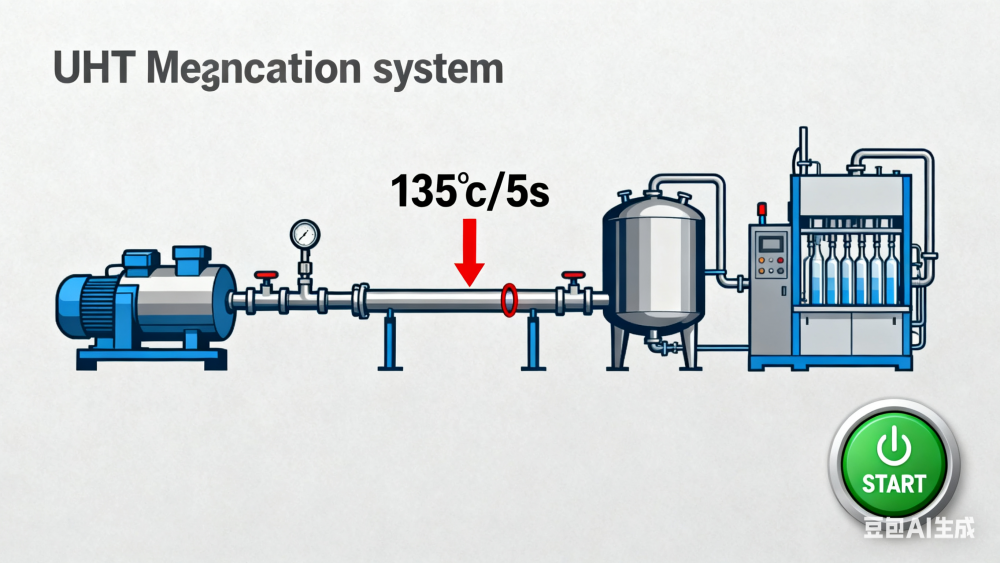

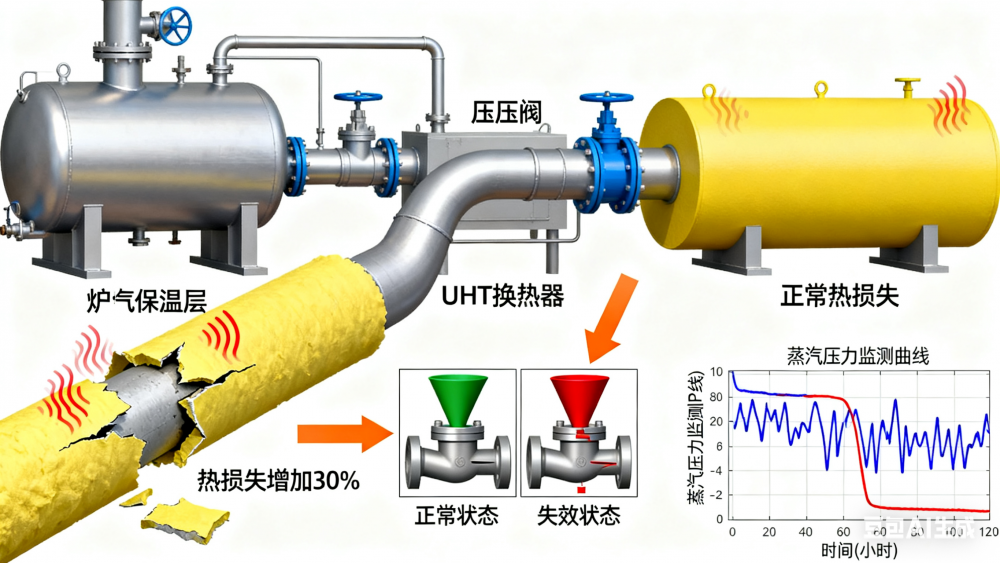

First, check the UHT system: Check if the steam pressure is stable and if the temperature sensor is calibrated. Check if there is any blockage in the holding tube that causes "short circuit." Confirm that the sterilization temperature and time (such as 135°C / 5s) meet the standard. Check if the sterile tank, filling head, and other subsequent links are contaminated and perform the SIP sterilization procedure. The sampling point should be away from dead ends to ensure representativeness.

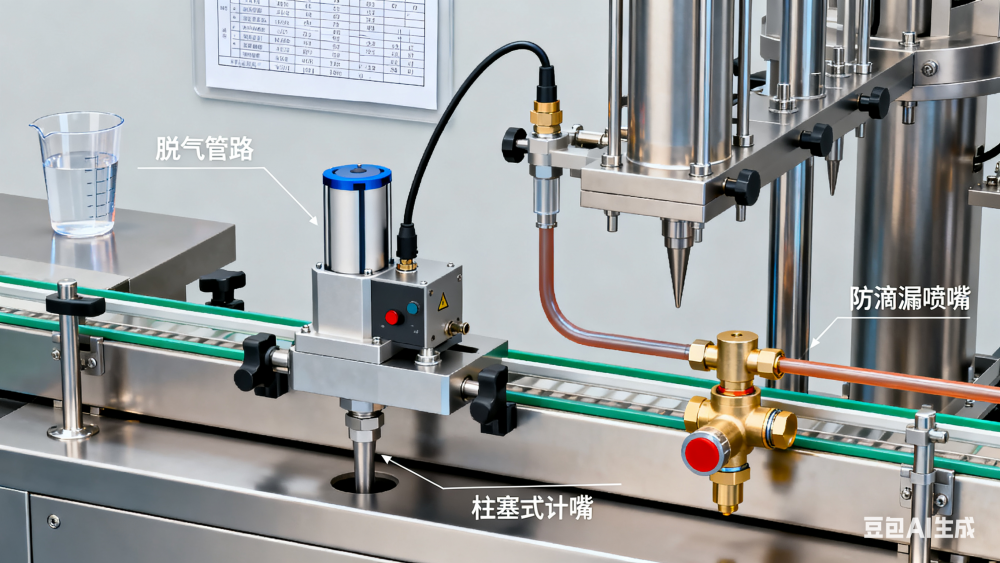

3. ) quantity is not accurate or splashing

Check if there is any blockage in the liquid level sensor, solenoid valve or plunger of the filling machine. Adjust the filling speed and back pressure (for carbonated beverages). Check for air bubbles in the pipeline and degas it before filling if necessary. Calibrate the filling head regularly to ensure measurement accuracy.

The CIP cleaning is not complete, residual odor remains.

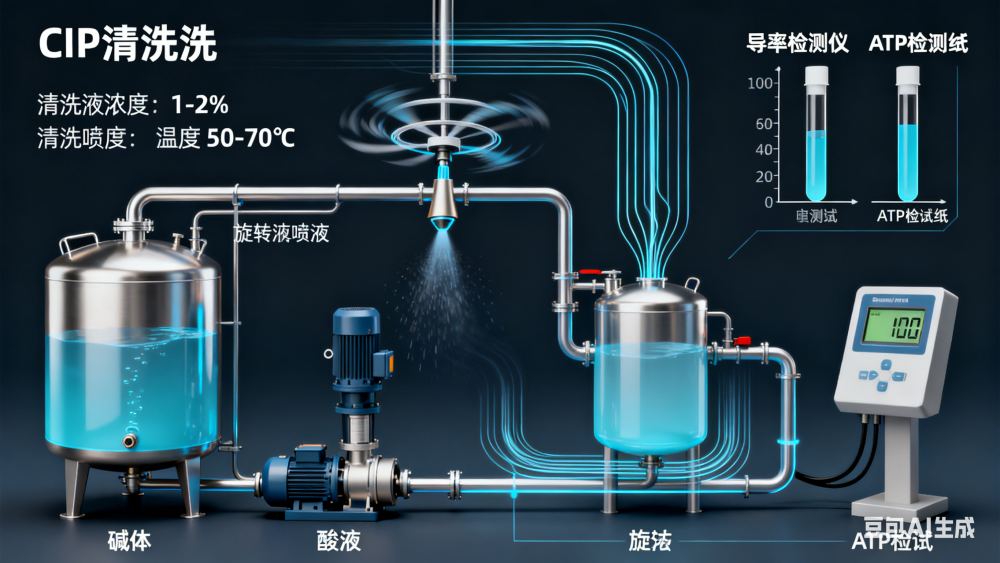

Commonly seen after switching products or prolonged downtime. Check that cleaning fluid concentration (alkaline 1-2%, acid 1-2%), temperature (50-70°C), and time meet standards. Confirm that nozzles rotate normally, and there are no blind ends in pipelines. For stubborn protein residue, increase enzyme cleaning procedures. After cleaning, take samples to test conductivity or ATP to verify cleanliness.

5, pipe blockage or flow decline

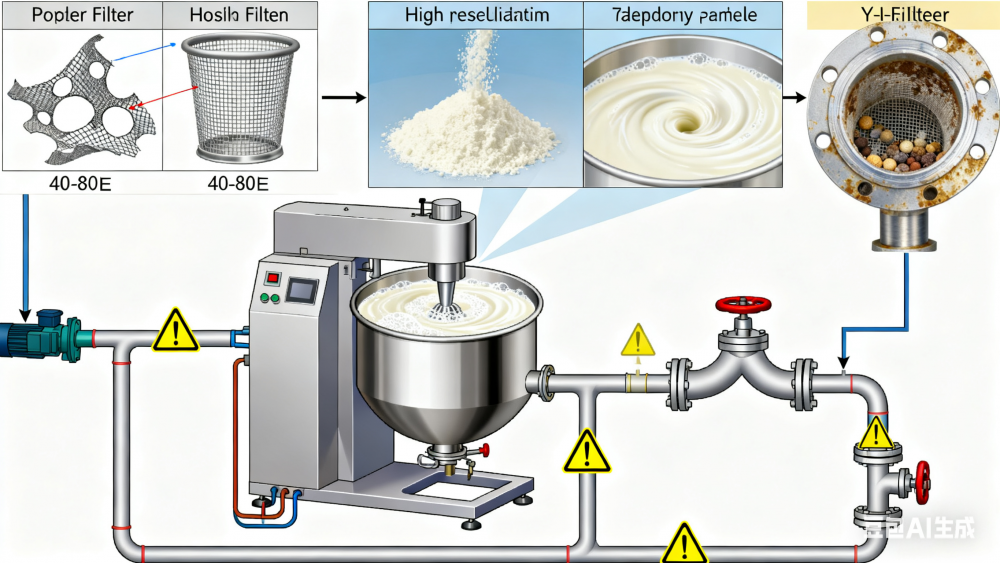

Multiple causes such as large meat granules or lumps in milk powder. Check if the raw material filter (recommended 40-80 mesh) is damaged. Optimize milk powder premix technology and use high shear dissolution. Check the Y-type filter before the pump and clean impurities in time. Avoid long-term static storage of materials in pipelines.

6, abnormal increase in steam consumption

Check if there is damage to the insulation of the UHT or SIP system, leakage in the valve, or failure of the trap. Confirm that the sterilization temperature setting is reasonable and avoid excessive heating. Monitor fluctuations in steam pressure and install a pressure regulator if necessary.

Tags: Juice and dairy product pilot production line, Common problem, Solution sharing